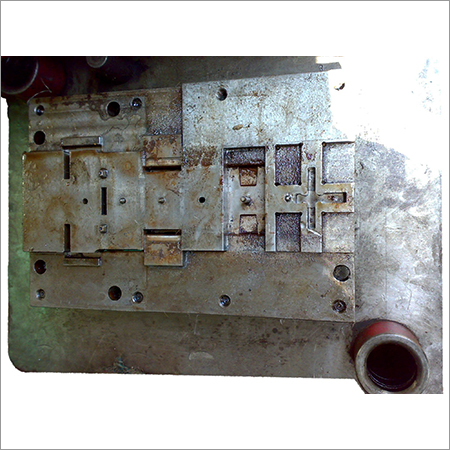

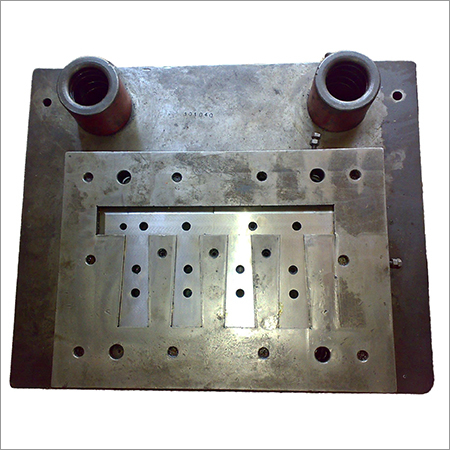

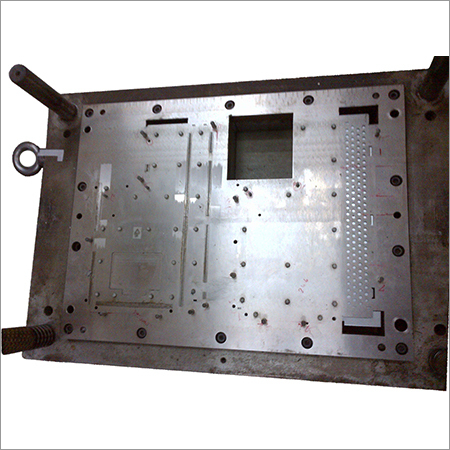

Progressive Tool

Progressive Tool Specification

- Application

- Sheet Metal Stamping, Blanking, Piercing

- Thickness

- Upto 12 mm

- Components

- Die, Punch, Stripper Plate, Guide Pillar, Guide Bush, Bottom Plate, Top Plate

- Hole Size

- Custom as per drawing/specification

- Load Capacity

- Suitable for High Production

- Other Features

- High precision, High durability, Multi-stage operation, Corrosion resistance

- Shape

- Rectangular

- Usage

- Industrial

- Material

- High Speed Steel (HSS), Mild Steel (MS)

- Product Type

- Progressive Tool

- Color

- Silver

- Surface Finishing

- Polished

- Manufacturing Technique

- CNC Machined

- Tolerance

- ±0.01 mm

- Automation Grade

- Semi-Automatic / Automatic

- Packaging Type

- Wooden Box/Custom

Progressive Tool Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Delivery Time

- 10 Days

- Main Export Market(s)

- Central America, Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

About Progressive Tool

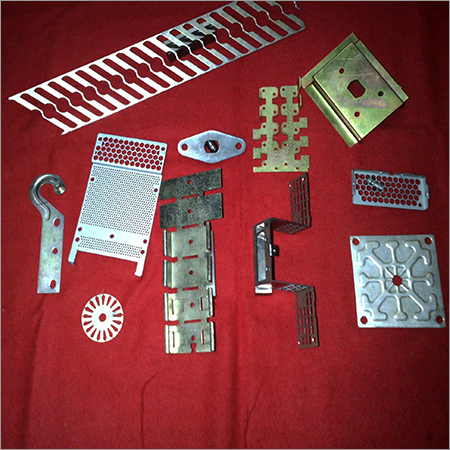

Clients can avail from us a wide collection of Progressive Tool that is crafted by our skilled engineers using high grade raw materials in line with the set international standards. It is widely used in the manufacturing process of electronic components and other kinds of stamping parts. Offered in various designs, finishes and other technical specifications in order to meet the diverse needs of our clients, this is widely demanded in various kinds of industrial applications. Further, we are offering this Progressive Tool at most competitive prices.

Features:

-

High strength

-

Corrosion resistance

-

Longer service life

-

Maintenance free

Advanced CNC Machining for Precision

Every Progressive Tool is manufactured using high-precision CNC machining technology, ensuring outstanding accuracy with tolerances as tight as 0.01 mm. This meticulous process delivers uniformity and repeatability across all components, supporting the rigorous demands of industrial sheet metal processing jobs.

Versatile Designs for Industrial Use

Our tools are built for flexibility, accommodating custom hole sizes and rectangular shapes to perfectly match your drawings or specifications. They are designed for heavy-duty, high-throughput applications, ideal for stamping, blanking, and piercing operations in demanding production environments.

High Durability and Corrosion Resistance

Crafted from premium High Speed Steel (HSS) or Mild Steel (MS), each Progressive Tool undergoes a polished surface treatment. This enhances both durability and resistance to corrosion, giving them a longer service life even in challenging industrial conditions.

FAQ's of Progressive Tool:

Q: How is the precision of the Progressive Tool maintained during manufacturing?

A: The Progressive Tool is manufactured using advanced CNC machining, which ensures tight tolerances of 0.01 mm, resulting in high-precision and consistent components for industrial applications.Q: What materials are available for the Progressive Tool's construction?

A: Our Progressive Tools are made from either High Speed Steel (HSS) or Mild Steel (MS), depending on your application requirements and desired durability.Q: When should a semi-automatic or automatic grade be selected?

A: Choose the semi-automatic grade for processes requiring operator intervention or frequent adjustments, while the automatic grade is best suited for continuous, high-volume production lines to enhance efficiency and reduce manual labor.Q: Where is the Progressive Tool used most effectively?

A: These tools are ideally used in industrial sheet metal operations like stamping, blanking, and piercing, where high load capacity and multi-stage processes are required for large-scale manufacturing.Q: What is the process involved in customizing hole sizes and shapes?

A: Hole sizes and shapes are manufactured precisely as per client drawings or specifications using CNC precision, ensuring each component fits your exact project requirements.Q: How does packaging ensure the safety of the Progressive Tool during delivery?

A: Tools are securely packed in wooden boxes or custom packaging to prevent damage during transportation, maintaining the tool's quality and integrity upon delivery.Q: What are the main benefits of using this Progressive Tool in industrial production?

A: The tool provides high precision, durability, corrosion resistance, and supports multi-stage operations, all of which contribute to efficient, high-volume production and reduced maintenance downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Press Tool Category

Progressive Press Tools

Minimum Order Quantity : 1 , , Unit

Application : Sheet Metal Stamping, Automobile, Electrical, and Engineering Industries

Thickness : 1 to 6 mm

Product Type : Progressive Press Tools

Components : Die Sets, Punches, Strippers, Pilots

Usage : Industrial

Metal Pressed Components

Minimum Order Quantity : 1 , , Unit

Application : Automotive & Industrial Machinery

Thickness : 2 mm to 6 mm

Product Type : Metal Pressed Components

Components : Metal Pressed Components

Usage : Industrial

Press Tool

Minimum Order Quantity : 1 , , Unit

Application : Sheet Metal Forming, Blanking, Piercing, Bending

Thickness : 2 mm to 10 mm

Product Type : Press Tool

Components : Die, Punch, Stripper Plates, Guide Pillars, Guide Bushes

Usage : Industrial

Precision Press Tool

Minimum Order Quantity : 1 Set

Application : Automotive, Electronics, Industrial Manufacturing

Thickness : Standard 4 mm (Customizable)

Product Type : Precision Press Tool

Components : Die, Punch, Stripper Plate, Base Plate, Guide Pillars, Bushings

Usage : Industrial

Send Inquiry

Send Inquiry