Progressive Press Tools

Progressive Press Tools Specification

- Application

- Sheet Metal Stamping, Automobile, Electrical, and Engineering Industries

- Thickness

- 1 to 6 mm

- Hole Size

- 0.5 to 50 mm

- Other Features

- High Precision, Long Service Life, Corrosion Resistant

- Load Capacity

- Up to 50 Ton

- Shape

- Custom (Rectangular, Circular, etc.)

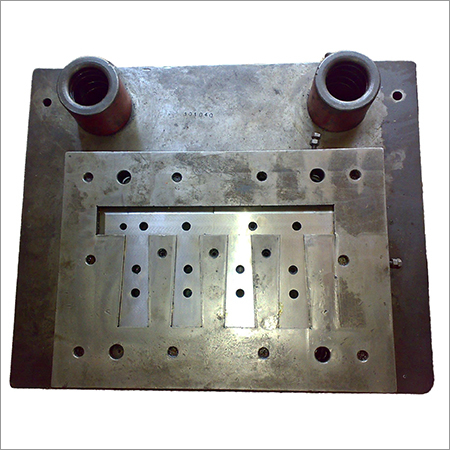

- Components

- Die Sets, Punches, Strippers, Pilots

- Usage

- Industrial

- Material

- High Speed Steel, Carbide, Tool Steel

- Product Type

- Progressive Press Tools

- Color

- grey

- Surface Finishing

- Polished

- Design

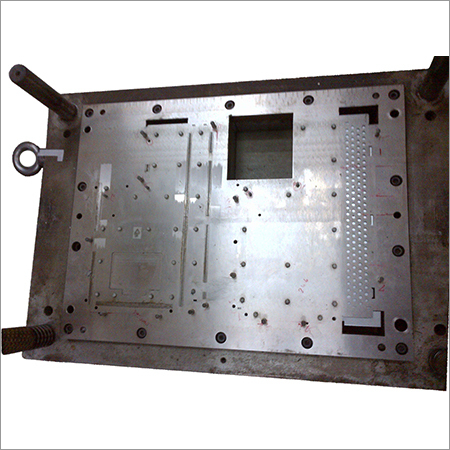

- Customized Designs Available

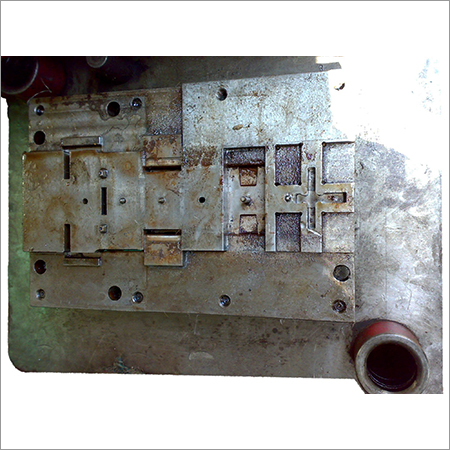

- Manufacturing Process

- CNC Machined / EDM

- Tolerance

- ±0.01 mm

- Maintenance

- Low

- Packaging Type

- Wooden Box

- Automation Grade

- Semi-Automatic / Automatic

Progressive Press Tools Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Cash Advance (CA), Telegraphic Transfer (T/T), Cheque

- Delivery Time

- 10 Days

- Main Export Market(s)

- Central America, Australia, North America, South America, Eastern Europe, Middle East, Africa, Asia, Western Europe

- Main Domestic Market

- All India

About Progressive Press Tools

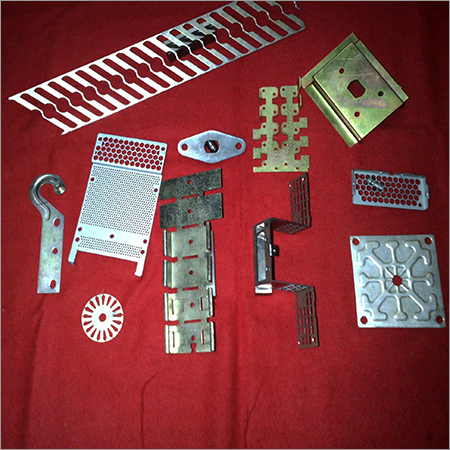

Progressive Press Tool from R. K. Engineers can be availed at market leading price. This kind of tool is developed following the defined industrial standards. Quality material is utilized in the fabrication process by the personnel for excellent strength, elevated durability, rugged design and rust resistance.

Features:

-

Elevated durability

-

Rugged design

-

Excellent strength

-

Rust resistance

Precision Engineering for Industrial Demands

Our progressive press tools are designed to meet the demanding requirements of industrial applications. With advanced CNC and EDM manufacturing, each component maintains high accuracy, ensuring reliability in sheet metal stamping. The customized design options allow you to match your exact specifications, from die sets to punches, strippers, and pilots. Coupled with various material selections and surface finishes, our tools deliver consistent results for every production batch.

Versatile and Durable Solutions

Crafted from top-grade high-speed steel, carbide, and tool steel, these tools promise lasting performance even in challenging industrial settings. Their polished finish and corrosion-resistant properties enhance operational longevity. Whether for the automobile, electrical, or engineering sectors, our tools are suitable for complex, high-precision jobs, handling loads up to 50 tons. Every order is securely shipped in a wooden box for maximum protection.

FAQ's of Progressive Press Tools:

Q: How are the progressive press tools customized for specific industrial needs?

A: The design team collaborates closely with clients to deliver progressive press tools tailored in shape, thickness, hole size, and overall configuration. Whether your requirement is rectangular, circular, or another custom shape, each tool is manufactured according to your production needs, ensuring high precision and compatibility.Q: What is the main benefit of using semi-automatic or automatic progressive press tools?

A: By integrating semi-automatic or automatic features, our press tools boost manufacturing efficiency, reduce manual intervention, and promote consistent product quality. This automation significantly enhances productivity and minimizes errors, making it ideal for high-volume industrial applications.Q: When should I opt for CNC machined or EDM processed press tools?

A: CNC machining and EDM processes offer superior accuracy and intricate detailing, making them the optimal choices when your project requires stringent tolerances (0.01 mm) and custom geometries. You should select these processes for complex stampings and projects demanding high repeatability.Q: Where are your progressive press tools typically used?

A: Our tools are used extensively in the automobile, electrical, and engineering sectors for various sheet metal stamping applications. Their robust build and high precision make them suitable for demanding industrial environments both in India and abroad.Q: How do I maintain these press tools to ensure longevity?

A: Thanks to their low-maintenance design and corrosion-resistant finishes, periodic inspections and routine cleaning are generally sufficient. Lubricate moving parts as needed and store tools in their protective packaging when not in use to maximize service life.Q: What advantages do high-speed steel and carbide materials offer for press tools?

A: High-speed steel and carbide provide exceptional durability and wear resistance, even under high loading and continuous operation. These materials ensure your tools maintain precision and edge integrity across extended manufacturing runs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Press Tool Category

Metal Pressed Components

Minimum Order Quantity : 1 , , Unit

Surface Finishing : Zinc Plated

Material : Mild Steel

Load Capacity : Up to 200 Kg

Color : Silver

Application : Automotive & Industrial Machinery

Progressive Tool

Minimum Order Quantity : 1 , , Unit

Surface Finishing : Polished

Material : High Speed Steel (HSS), Mild Steel (MS)

Load Capacity : Suitable for High Production

Color : Silver

Application : Sheet Metal Stamping, Blanking, Piercing

Press Tool

Minimum Order Quantity : 1 , , Unit

Surface Finishing : Polished, Matte Finish

Material : HighSpeed Steel (HSS), Tool Steel

Load Capacity : Up to 50 tons

Color : Grey

Application : Sheet Metal Forming, Blanking, Piercing, Bending

Precision Press Tool

Minimum Order Quantity : 1 Set

Surface Finishing : Polished, Corrosionresistant

Material : Highgrade Tool Steel

Load Capacity : Up to 10 Tons

Color : Silver

Application : Automotive, Electronics, Industrial Manufacturing

Send Inquiry

Send Inquiry