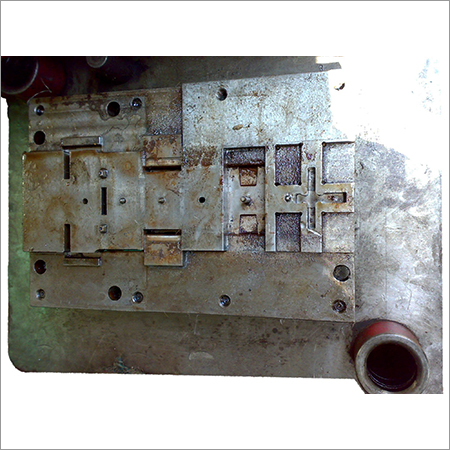

Precision Press Tool

Precision Press Tool Specification

- Application

- Automotive, Electronics, Industrial Manufacturing

- Other Features

- High accuracy, Long service life, Easy maintenance

- Components

- Die, Punch, Stripper Plate, Base Plate, Guide Pillars, Bushings

- Hole Size

- Precise as per drawing/specification

- Shape

- Rectangular

- Thickness

- Standard 4 mm (Customizable)

- Load Capacity

- Up to 10 Tons

- Usage

- Industrial

- Material

- High-grade Tool Steel

- Product Type

- Precision Press Tool

- Color

- Silver

- Surface Finishing

- Polished, Corrosion-resistant

- Compatibility

- Suitable for most Press Machines

- Packaging Type

- Wooden Box / Carton

- Tolerance

- ±0.01 mm

- Customization

- Available as per requirements

- Operating Temperature

- Up to 250°C

- Hardness

- HRC 56-62

Precision Press Tool Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Cash Advance (CA), Telegraphic Transfer (T/T), Cheque

- Delivery Time

- Days

- Main Domestic Market

- All India

About Precision Press Tool

Press tool is basically a tool utilized in the production of sheet metal components. It uses force, whether hydraulic, pneumatic or mechanical, in the production of components at high volumes. This tool can be out to use for performing operations, trimming, forging, forming, bending, piercing, blanking, etc. Our designers and engineers together create a versatile line of press tools for customers.

Features:.

- The high strength and tough tool can be used for long

- This can resist rust & impact

- This is known for precise engineering

- It has longer service life

Superior Precision and Performance

Our Precision Press Tool stands out for its remarkable 0.01 mm tolerance, making it the preferred choice for automotive, electronics, and industrial manufacturing. Crafted with high-grade tool steel and polished for corrosion resistance, it ensures consistency and durability during prolonged use even at high temperatures.

Customizable and Versatile Applications

Designed for flexibility, this tool accommodates custom thicknesses and hole sizes as specified in technical drawings. Its compatibility with most press machines guarantees broad usability, from manufacturing automotive parts to intricate electronic components, with each component engineered for easy maintenance and a long service life.

FAQ's of Precision Press Tool:

Q: How is the Precision Press Tool customized according to the client's requirements?

A: Customization is achieved by adapting the tool's thickness, hole sizes, and dimensions as per your technical drawings or specifications. Our team works closely with clients to deliver tailor-made solutions for unique applications.Q: What materials are used in the construction of the Precision Press Tool?

A: This press tool is made from high-grade tool steel, renowned for its superior hardness (HRC 56-62) and polished, corrosion-resistant surface. This ensures optimal durability and consistent performance over time.Q: When is it best to use the Precision Press Tool in industrial processes?

A: The tool is ideal for use in environments requiring high accuracy and durability, such as automotive, electronics, and general industrial manufacturing. It performs reliably in operations involving loads up to 10 tons and temperatures up to 250C.Q: Where can the Precision Press Tool be implemented most effectively?

A: It integrates seamlessly with most press machines and is broadly applicable in settings like automotive plants, electronics workshops, and component manufacturing facilities. Its rectangular shape and modular components support various industrial set-ups.Q: What is the process for maintaining the Precision Press Tool?

A: Routine maintenance involves regular cleaning, lubrication of moving parts, and inspection for wear. Thanks to its polished, corrosion-resistant surface, upkeep is easy and contributes to the tool's extended service life.Q: How does the Precision Press Tool benefit users in terms of productivity and quality?

A: With high accuracy, robust load capacity, and easy compatibility, the press tool minimizes downtime, boosts productivity, and ensures consistently high-quality output, making it a valuable asset for any precision-driven operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Press Tool Category

Progressive Press Tools

Minimum Order Quantity : 1 , , Unit

Load Capacity : Up to 50 Ton

Shape : Custom (Rectangular, Circular, etc.)

Usage : Industrial

Other Features : High Precision, Long Service Life, Corrosion Resistant

Material : High Speed Steel, Carbide, Tool Steel

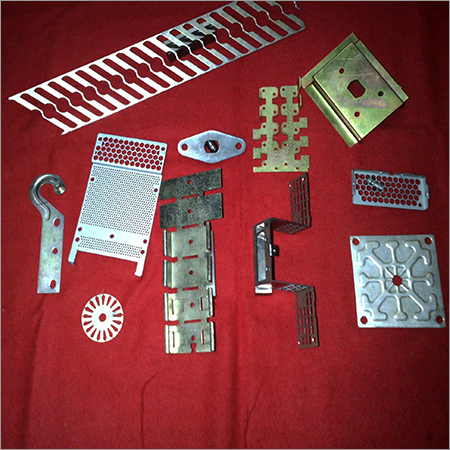

Metal Pressed Components

Minimum Order Quantity : 1 , , Unit

Load Capacity : Up to 200 Kg

Shape : Rectangular

Usage : Industrial

Other Features : Corrosion Resistant, Precision Stamped

Material : Mild Steel

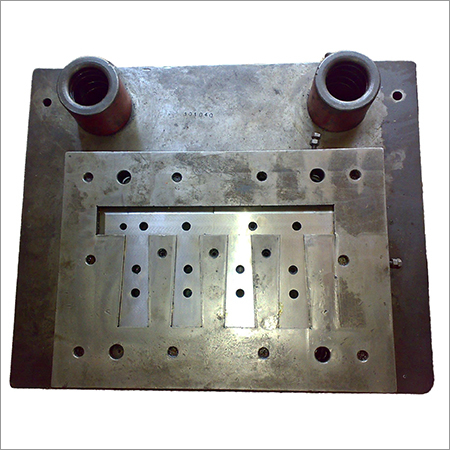

Progressive Tool

Minimum Order Quantity : 1 , , Unit

Load Capacity : Suitable for High Production

Shape : Rectangular

Usage : Industrial

Other Features : High precision, High durability, Multistage operation, Corrosion resistance

Material : High Speed Steel (HSS), Mild Steel (MS)

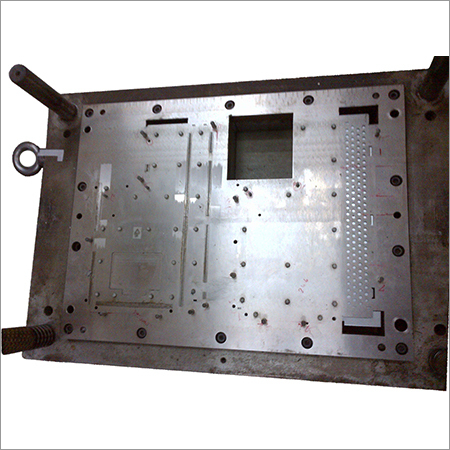

Press Tool

Minimum Order Quantity : 1 , , Unit

Load Capacity : Up to 50 tons

Shape : Rectangular, Square, Custom

Usage : Industrial

Other Features : High Durability, Precise Cutting, Corrosion Resistance

Material : HighSpeed Steel (HSS), Tool Steel

Send Inquiry

Send Inquiry