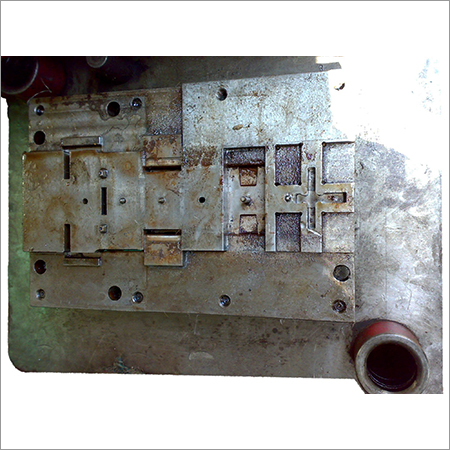

Press Tool

Press Tool Specification

- Other Features

- High Durability, Precise Cutting, Corrosion Resistance

- Hole Size

- 1 mm to 50 mm

- Shape

- Rectangular, Square, Custom

- Application

- Sheet Metal Forming, Blanking, Piercing, Bending

- Load Capacity

- Up to 50 tons

- Components

- Die, Punch, Stripper Plates, Guide Pillars, Guide Bushes

- Thickness

- 2 mm to 10 mm

- Usage

- Industrial

- Material

- High-Speed Steel (HSS), Tool Steel

- Product Type

- Press Tool

- Color

- Grey

- Surface Finishing

- Polished, Matte Finish

- Manufacturing Process

- CNC Machined & Hardened

- Tolerance

- ±0.02 mm

- Maintenance

- Low, Easy to Maintain

- Life Span

- Up to 1,000,000 strokes

- Operating Temperature

- Up to 200°C

Press Tool Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Cash Advance (CA), Telegraphic Transfer (T/T), Cheque

- Delivery Time

- 10 Days

- Main Export Market(s)

- Central America, Australia, North America, South America, Eastern Europe, Middle East, Asia, Western Europe, Africa

- Main Domestic Market

- All India

About Press Tool

Companies that create sheet metal tools use Press Tools. Different kinds of operations are possible using press tools, like bending, forming, forging, blanking, piercing and trimming. Our company, R. K. Engineers can make available Press Tool, which can be utilized for changing the shape of workpiece by the application of pressure. Tough and study in design, the press tool can be provided in several specifications.

Features:

- The tool is resistant to impact and corrosion

- The metal alloy used in the fabrication ensure longer life

- It can bear heavy loads

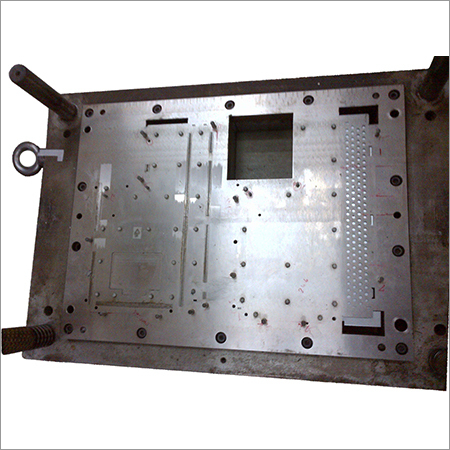

High-Precision Manufacturing Process

Each press tool is CNC machined and hardened, ensuring exceptional accuracy with a tolerance of 0.02 mm. This process guarantees consistent performance across all components, including the die, punch, and guide elements, resulting in smoother operations and extended tool life.

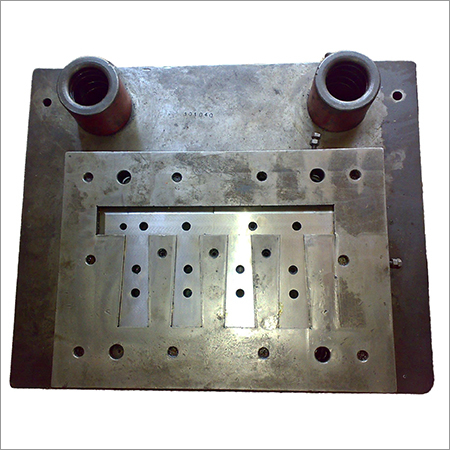

Robust Material Choices for Longevity

Using high-speed steel (HSS) and tool steel, this press tool is built to withstand the rigors of industrial environments. These materials provide high load capacity (up to 50 tons), enhanced corrosion resistance, and a lifespan of up to 1,000,000 strokes.

Versatility and Customization

Available in thicknesses from 2 mm to 10 mm and adaptable to various hole sizes and shapes, this press tool suits diverse manufacturing needs. The tool can be finished in either polished or matte, and is designed for multiple industrial tasks, including forming, blanking, and piercing.

FAQ's of Press Tool:

Q: How is the press tool manufactured and what benefits does CNC machining offer?

A: The press tool is manufactured using advanced CNC machining and hardening techniques. CNC machining ensures precise dimensions with tight tolerances of 0.02 mm, resulting in consistent quality and performance, which is critical for industrial applications.Q: What materials are used for the press tool, and how do they enhance its durability?

A: This press tool is crafted from high-speed steel (HSS) and tool steel, both known for their robustness and ability to withstand high loads (up to 50 tons). These materials contribute to the tool's exceptional durability, corrosion resistance, and long operational life.Q: When should this press tool be used in manufacturing processes?

A: The press tool is ideal for industrial tasks requiring high precision, such as sheet metal forming, blanking, piercing, and bending. It is particularly suitable in environments where a tool must operate under high temperatures (up to 200C) and frequent use.Q: Where is this press tool most commonly applied?

A: It is predominantly used in industrial manufacturing settings, especially in sheet metal processing industries across India and suitable for export usage due to its high durability and precision.Q: What is the maintenance process for this press tool?

A: The tool is designed for low and easy maintenance, thanks to its polished or matte corrosion-resistant surface and quality construction. Regular cleaning and periodic inspections are generally sufficient to maintain optimal functionality.Q: How does the customizable nature of the press tool benefit industrial operations?

A: Customizable hole sizes (1 mm to 50 mm), thickness (2 mm to 10 mm), and shapes (rectangular, square, or custom) allow manufacturers to tailor the tool to specific project requirements, increasing efficiency and reducing production downtime.Q: What are the main advantages of using this press tool over others?

A: Key benefits include precise cutting, high durability, long lifespan (up to 1,000,000 strokes), resistance to corrosion, and the ability to handle heavy loads while maintaining accuracy and ease of maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Press Tool Category

Progressive Tool

Minimum Order Quantity : 1 , , Unit

Product Type : Progressive Tool

Surface Finishing : Polished

Color : Silver

Thickness : Upto 12 mm

Load Capacity : Suitable for High Production

Progressive Press Tools

Minimum Order Quantity : 1 , , Unit

Product Type : Progressive Press Tools

Surface Finishing : Polished

Color : grey

Thickness : 1 to 6 mm

Load Capacity : Up to 50 Ton

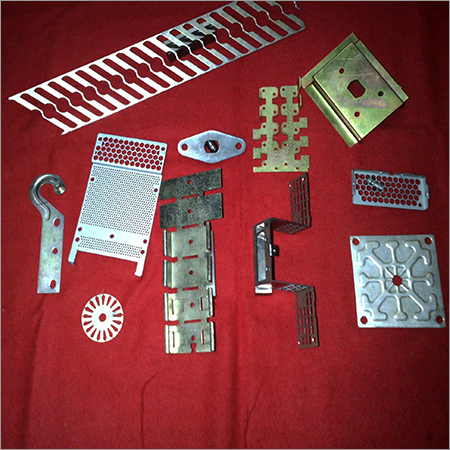

Metal Pressed Components

Minimum Order Quantity : 1 , , Unit

Product Type : Metal Pressed Components

Surface Finishing : Zinc Plated

Color : Silver

Thickness : 2 mm to 6 mm

Load Capacity : Up to 200 Kg

Precision Press Tool

Minimum Order Quantity : 1 Set

Product Type : Precision Press Tool

Surface Finishing : Polished, Corrosionresistant

Color : Silver

Thickness : Standard 4 mm (Customizable)

Load Capacity : Up to 10 Tons

Send Inquiry

Send Inquiry