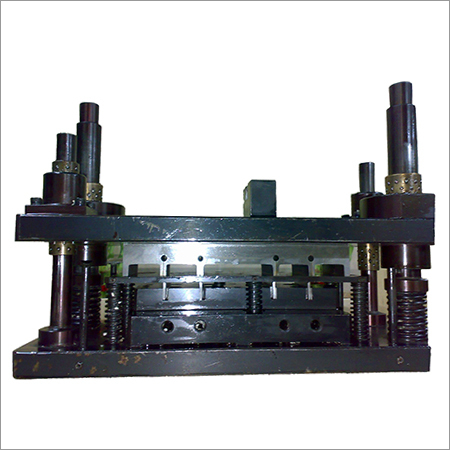

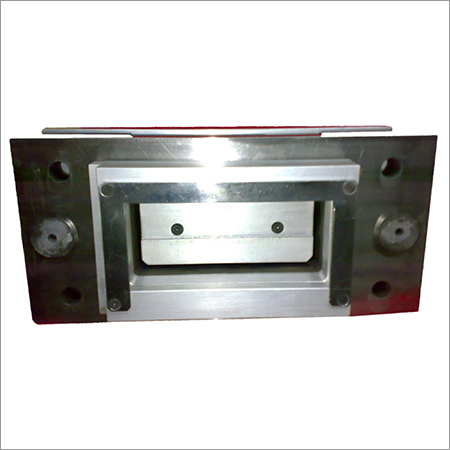

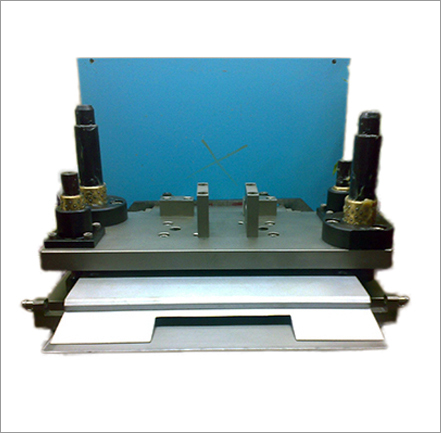

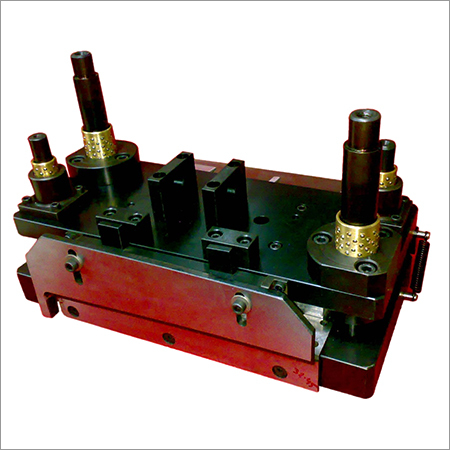

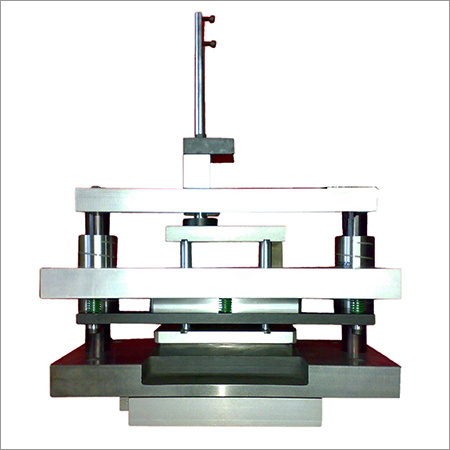

Press Tool Dies

Press Tool Dies Specification

- Mould Base

- High Performance Metal Base

- Working Process

- Other

- Tolerance

- 0.02 mm

- Life Span

- Long Operational Life

- Core Material

- Premium Alloy Steel

- Usage

- Industrial

- Material

- Other

- Shaping Mode

- Other

- Size

- 230 inches

- Product Type

- Pressure Tool Dies

- Punch Dies

- Tempered Steel Punches

- Die Head

- Precision Ground Die Head

- Color

- Silver

- Surface Finish

- Mirror Polished

- Application

- Sheet Metal Forming

- Weight

- Approx. 25 kg

- Hardness

- 58-60 HRC

- Cavity

- Single / Multiple as per requirement

Press Tool Dies Trade Information

- Minimum Order Quantity

- 01 Ton

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- loading

- Main Export Market(s)

- Central America, Eastern Europe, North America, Middle East, South America, Asia, Western Europe, Australia, Africa

- Main Domestic Market

- All India

- Certifications

- iso

About Press Tool Dies

Ours is a renowned company engaged in manufacturing of Press Tool Dies. A number of manufacturing industries demand these dies for producing components in simple to complex shapes and at high volumes. Customers when availing these Press Tool Dies from us, can be assured of the high tensile strength, excellent performance, dimensional accuracy and corrosion resistance.

Features of Press Tool Dies:

-

Excellent performance

-

Dimensional accuracy

-

High tensile strength

-

Resistant to corrosion

Superior Surface Finish and Material Quality

Each press tool die boasts a flawless mirror-polished surface for minimal friction and improved release properties during forming. Constructed with a high-performance metal base and premium alloy steel core, these dies ensure exceptional strength and resistance to wear, supporting demanding manufacturing schedules and tough industrial environments.

Accurate Forming for Industrial Efficiency

With a tolerance of 0.02 mm and precision ground die heads, our dies deliver outstanding dimensional accuracy and consistency in sheet metal forming. The cavity is customizable-available as single or multiple-making it ideal for a variety of production needs where precision and repeatability are essential.

Long Life Span and Reliable Performance

Engineered for longevity, these press tool dies are heat-treated to achieve a hardness of 58-60 HRC, ensuring prolonged operational life even under high-volume production. Their robust construction and tempered steel punches guarantee resilience and maintain cutting edge sharpness over extended usage.

FAQ's of Press Tool Dies:

Q: How are these press tool dies typically used in industrial settings?

A: These dies are primarily employed for sheet metal forming operations in industrial environments. They facilitate a range of forming tasks, from cutting and bending to shaping metal sheets according to exact specifications, ensuring efficient and precise production processes.Q: What materials are utilized in the construction of the press tool dies?

A: The dies are manufactured using a premium alloy steel core combined with a high-performance metal base. This quality construction enhances the die's hardness, structural integrity, and longevity, making it suitable for intensive industrial use.Q: When should I opt for single or multiple cavity dies?

A: Single cavity dies are ideal for smaller production runs or prototypes, while multiple cavity dies are recommended for large-scale manufacturing when high production output and efficiency are required. The choice depends on your specific capacity and production demands.Q: Where are these press tool dies manufactured and supplied from?

A: These press tool dies are manufactured, exported, and supplied from India. As a trusted manufacturer and service provider, we ensure adherence to global quality standards and deliver our products to various international markets.Q: What is the process for ensuring the high surface finish and tight tolerance of the dies?

A: Our dies undergo advanced mirror polishing techniques and precision grinding of the die head. Coupled with exacting manufacturing practices, we consistently achieve a high surface finish and a tight dimensional tolerance of 0.02 mm for reliable forming results.Q: How does the product's design benefit industrial users?

A: The robust material selection, exacting finish, and precise engineering provide long operational life, high repeatability, and reduced maintenance needs. These attributes combine to increase productivity and minimize downtime in demanding industrial sheet metal forming applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Dies Category

Cutting Dies

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Punch Dies : Multiple configurations available

Material : Steel

Core Material : High Speed Steel (HSS)

Tolerance : 0.01 mm

Punching Tool

Price 10000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Punch Dies : Replaceable, carbidetipped

Material : Other

Core Material : HighSpeed Steel (HSS)

Tolerance : 0.01 mm

Precision Dies

Minimum Order Quantity : 1 , , Unit

Punch Dies : Carbide/Steel Punch Dies

Material : Steel

Core Material : Highgrade Alloy Steel

Tolerance : 0.005 mm

Precision Tool Dies

Minimum Order Quantity : 1 , , Unit

Punch Dies : Interchangeable Inserts

Material : Steel

Core Material : HighGrade Steel

Tolerance : 0.01 mm

Send Inquiry

Send Inquiry