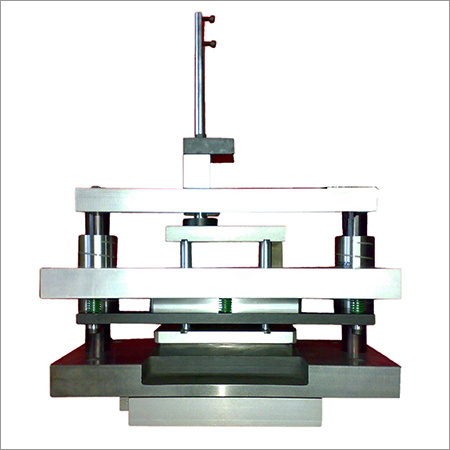

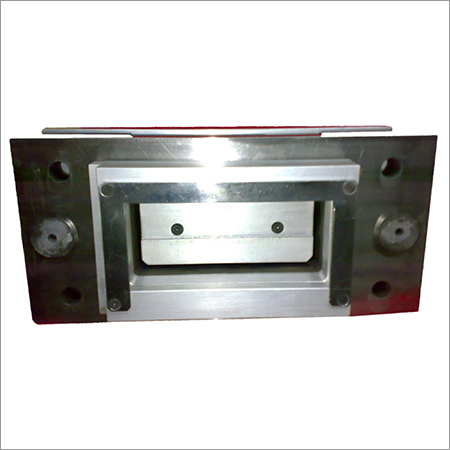

Punching Tool

Price 10000.00 INR/ Piece

Punching Tool Specification

- Tolerance

- 0.01 mm

- Core Material

- High-Speed Steel (HSS)

- Life Span

- Up to 500,000 cycles

- Working Process

- Precision Punching

- Mould Base

- Steel

- Usage

- Industrial

- Material

- Other

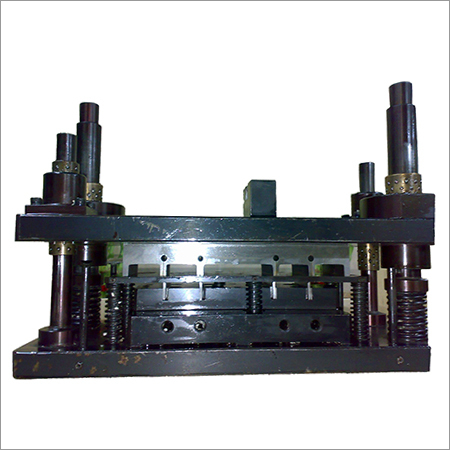

- Shaping Mode

- Punching

- Product Type

- Punching Tool

- Punch Dies

- Replaceable, carbide-tipped

- Die Head

- Hardened Steel

- Color

- Grey

Punching Tool Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Main Export Market(s)

- Central America, North America, Eastern Europe, Middle East, South America, Asia, Western Europe, Australia, Africa

- Main Domestic Market

- All India

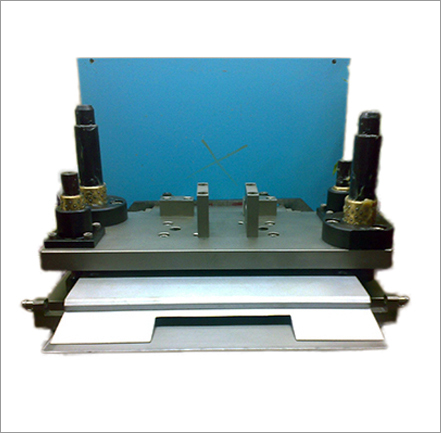

About Punching Tool

With our team of experienced professionals, we are able to bring forth Punching Tool, which can be attached to any tableting machine for medium to high-speed tablet production in industries. This professional team designs and manufactures the tool and assure dimensional accuracy, corrosion resistance, longer operations without any hassle and sturdy construction.

Features of Punching Tool:

- Sturdy construction

- Longer functional life

- Dimensional accuracy

- Corrosion resistance

Engineered for Precision and Longevity

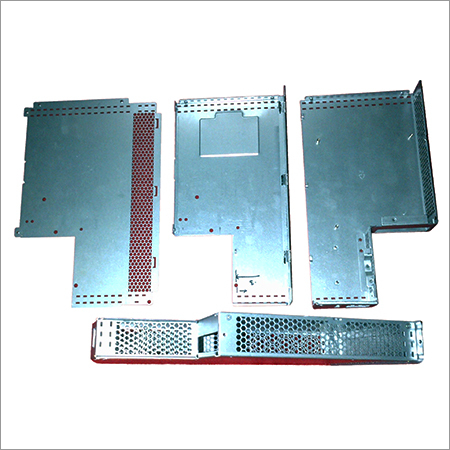

Our punching tool delivers high accuracy in precision punching applications, supporting sheet thicknesses from 0.5 mm to 5 mm. The tool's core components utilize high-speed steel and a hardened steel die head, positioned to endure demanding industrial cycles and deliver reliable results up to 500,000 operations. Its polished finish and corrosion resistance further enhance its longevity and performance.

Versatile Compatibility and User Benefits

Compatible with hydraulic and mechanical presses, this tool integrates seamlessly into diverse manufacturing setups. Customized sizing options ensure a tailored fit for specific requirements, while the low-maintenance and replaceable punch dies minimize downtime, reducing operational costs. Its robust construction makes it ideal for industries prioritizing precision and efficiency.

FAQ's of Punching Tool:

Q: How should the punching tool be maintained to achieve its maximum lifespan?

A: Routine maintenance is minimal due to the tool's robust design and corrosion-resistant materials. To maximize the tool's lifespan-up to 500,000 cycles-regularly inspect and, if needed, replace the carbide-tipped punch dies and lubricate the moving parts as recommended.Q: What materials and applications is the punching tool suitable for?

A: This tool is designed for industrial punching of metal sheets with thicknesses between 0.5 mm and 5 mm. It's ideal for various industries requiring precision punching, including automotive, electrical, and fabrication sectors.Q: When is it necessary to replace the punch dies?

A: Punch dies should be replaced when you notice a drop in cutting performance, increased burr formation, or after extended use approaching the tool's rated cycle life. The replaceable, carbide-tipped design makes this process straightforward.Q: Where can the punching tool be installed or used?

A: The punching tool is compatible with standard hydraulic and mechanical pressing machines commonly found in factories, workshops, and industrial plants involved in sheet metal processing.Q: How does the tool provide precision and corrosion resistance in industrial settings?

A: The tool's high-speed steel core, hardened die head, and polished surface finish together enable a tight tolerance of 0.01 mm while resisting wear and corrosion, ensuring consistent results and long-term performance even in demanding environments.Q: What are the benefits of customized sizing for the punching tool?

A: Customized sizing ensures an optimal fit for specific pressing machines or specialized manufacturing tasks, enhancing precision, reducing setup times, and improving workflow efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Dies Category

Press Tool Dies

Minimum Order Quantity : 01 Ton

Core Material : Premium Alloy Steel

Die Head : Precision Ground Die Head

Tolerance : 0.02 mm

Color : Silver

Usage : Industrial

Cutting Dies

Minimum Order Quantity : 1 Piece

Core Material : High Speed Steel (HSS)

Die Head : Hardened, Replaceable

Tolerance : 0.01 mm

Color : Black

Usage : Industrial

Industrial Dies

Minimum Order Quantity : 1 , , Unit

Core Material : Hardened Steel

Die Head : Interchangeable Die Assembly

Tolerance : 0.01 mm

Color : Silver

Usage : Die Casting

Precision Dies

Minimum Order Quantity : 1 , , Unit

Core Material : Highgrade Alloy Steel

Die Head : Hardened Steel Die Head

Tolerance : 0.005 mm

Color : Silver

Usage : Industrial

Send Inquiry

Send Inquiry