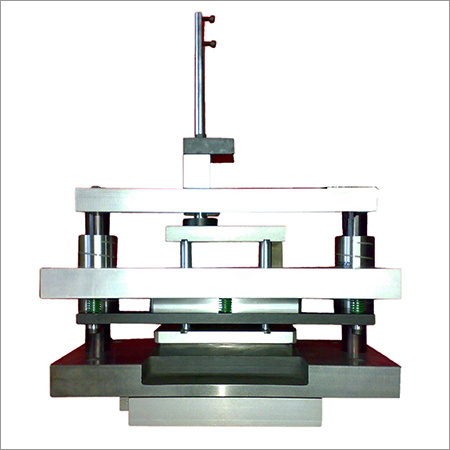

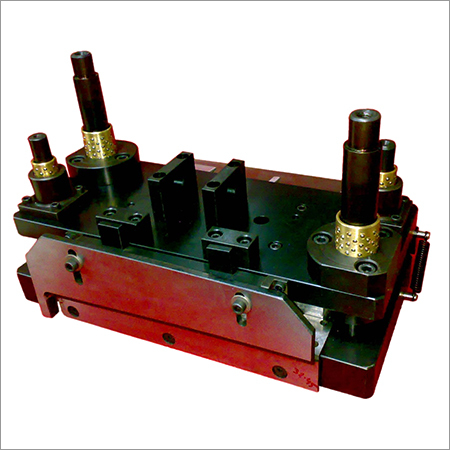

Precision Tool Dies

Precision Tool Dies Specification

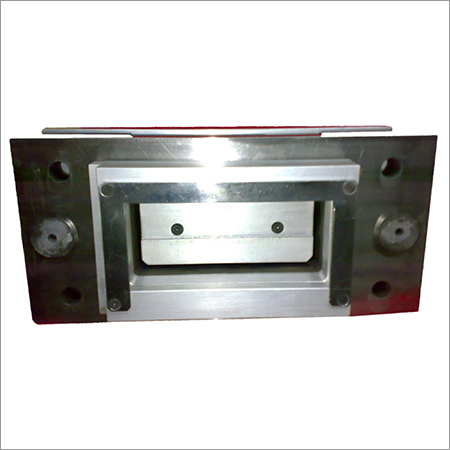

- Mould Base

- Custom Alloy Steel

- Life Span

- Up to 500,000 shots

- Tolerance

- 0.01 mm

- Core Material

- High-Grade Steel

- Working Process

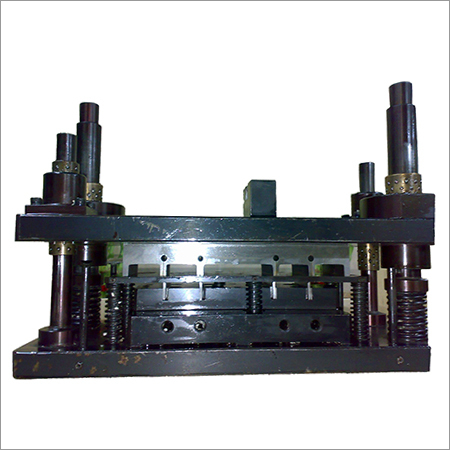

- CNC Machining / EDM / Grinding

- Usage

- Industrial

- Material

- Steel

- Shaping Mode

- Die Casting

- Product Type

- Precision Tool Dies

- Punch Dies

- Interchangeable Inserts

- Die Head

- Precision Hardened Steel

- Color

- Black

- Application

- Metal Forming, Stamping, Cutting

- Heat Treatment

- Tempered & Stress Relieved

- Hardness

- HRC 48-52

- Surface Finish

- Polished / Coated

- Customization

- Available as per Drawing or Sample

- Size

- As per requirement

Precision Tool Dies Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Delivery Time

- 10 Days

- Main Export Market(s)

- Central America, Asia, Australia, North America, Eastern Europe, Middle East, South America, Western Europe, Africa

- Main Domestic Market

- All India

About Precision Tool Dies

Our 2002 established manufacturing company brings to the market Precision Tool Dies. These dies are widely demanded in the national and international markets for their tolerance and ability to withstand temperature fluctuations. At our company, an experienced team utilizing modern technology fabricates these dies.

Features:

- Clients can expect perfect finish of tool dies and reliable operations

- These have resistance against corrosion resistance

- Made in a way to enhance durability

Engineered for Precision and Durability

Our tool dies are designed with meticulous attention to detail, combining premium materials like high-grade steel and custom alloy bases with advanced heat treatments. This ensures exceptional performance and a long operational life, meeting the complex requirements of metal forming and industrial stamping processes.

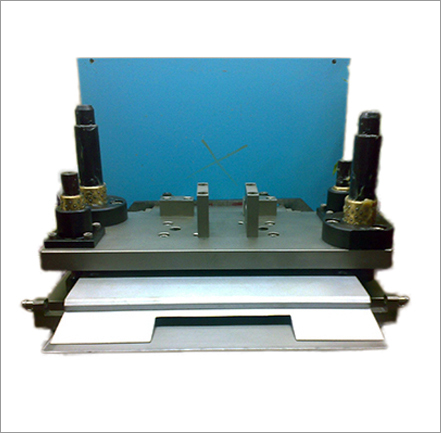

Custom Solutions for Industrial Needs

Every die we produce is tailored to specific customer drawings or samples. This high degree of customization guarantees optimal fit and function in your manufacturing operations. No matter the size or application, our precision dies provide reliable, repeatable results for your unique requirements.

FAQ's of Precision Tool Dies:

Q: How is the surface finish of the precision tool dies achieved?

A: The surface finish is obtained through a combination of precision machining, polishing, and optional coating processes, resulting in a smooth, durable die surface that enhances tool life and performance in metal forming and stamping operations.Q: What benefits do users gain from the dies' HRC 48-52 hardness range?

A: A hardness rating of HRC 48-52 provides a balanced combination of wear resistance and toughness, extending the life span of each die up to 500,000 shots even under high-stress, repetitive industrial applications.Q: When is customization of tool dies available for customers?

A: Customization is available at any stage of the order process. Clients can submit their unique drawings or samples, and our engineering team will tailor the dies to exact size, tolerance, and application requirements.Q: Where can these precision tool dies be used?

A: These dies are suitable for a wide range of industrial environments, including metal forming, stamping, cutting, and various manufacturing lines that require high accuracy and long-lasting tooling solutions.Q: What process steps are involved in manufacturing these tool dies?

A: Key manufacturing processes include CNC machining, electric discharge machining (EDM), grinding, and rigorous heat treatments like tempering and stress relief, ensuring each part meets strict dimensional and quality standards.Q: How do interchangeable punch dies and precision-hardened die heads improve usage?

A: Interchangeable inserts allow for quick die swaps and reduced downtime, while precision-hardened die heads contribute to consistent results, enhancing productivity and maintenance efficiency in high-volume production settings.Q: Why is tight tolerance important in these tool dies?

A: A tight tolerance of 0.01 mm ensures each die produces highly consistent parts, minimizing material waste and ensuring compatibility with demanding industrial applications where precision is critical.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Dies Category

Press Tool Dies

Minimum Order Quantity : 01 Ton

Usage : Industrial

Shaping Mode : Other

Working Process : Other

Punch Dies : Tempered Steel Punches

Cutting Dies

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Shaping Mode : Other, Press Mould

Working Process : Other, Stamping, Forming, Cutting

Punch Dies : Multiple configurations available

Punching Tool

Price 10000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Shaping Mode : Other, Punching

Working Process : Other, Precision Punching

Punch Dies : Replaceable, carbidetipped

Precision Dies

Minimum Order Quantity : 1 , , Unit

Usage : Industrial

Shaping Mode : Other, Stamping/Injection

Working Process : Other, Precision Machining, EDM, CNC Milling

Punch Dies : Carbide/Steel Punch Dies

Send Inquiry

Send Inquiry