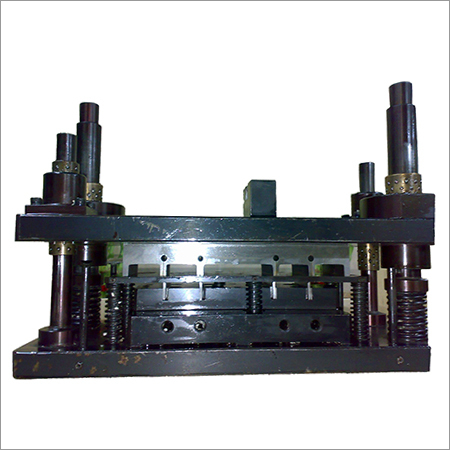

Cutting Dies

Price 1000 INR/ Piece

Cutting Dies Specification

- Mould Base

- Precision Ground Steel Base

- Life Span

- Up to 1 Million Cuts

- Core Material

- High Speed Steel (HSS)

- Working Process

- Stamping, Forming, Cutting

- Tolerance

- 0.01 mm

- Usage

- Industrial

- Material

- Steel

- Shaping Mode

- Press Mould

- Product Type

- Cutting Dies

- Punch Dies

- Multiple configurations available

- Die Head

- Hardened, Replaceable

- Color

- Black

- Size

- Standard and Custom sizes available

- Packaging Type

- Wooden Box/Carton

- Surface Finish

- Polished

- Thickness Range

- 0.5mm - 10mm

- Application

- Metal, Paper, Plastic Cutting

- Heat Treatment

- Vacuum Hardened

- Cutting Edge Hardness

- 58-62 HRC

- Design

- Customizable

Cutting Dies Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 3 Days

- Main Export Market(s)

- Central America, North America, Eastern Europe, Middle East, South America, Asia, Western Europe, Australia, Africa

- Main Domestic Market

- All India

About Cutting Dies

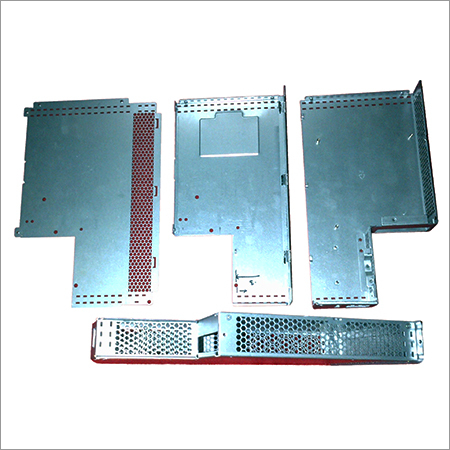

The Die Cutting Tools in the offering find usage in several industries for shaping material into desired forms. The in-house manufactured and developed cutting tools comprise sharp cutting blades for cleaving material into desired shape. When using Die Cutting Tools from R. K. Engineers, one can be assured of getting adequate product quality.

We are offering a high quality range of Die Cutting Tools. These tools are very popular in every industry...

Features:

- We provide dimensionally accurate cutting tools

- These tools feature high tensile strength

- The surface of the tools are excellently finished

- The body of the tool is corrosion resistant

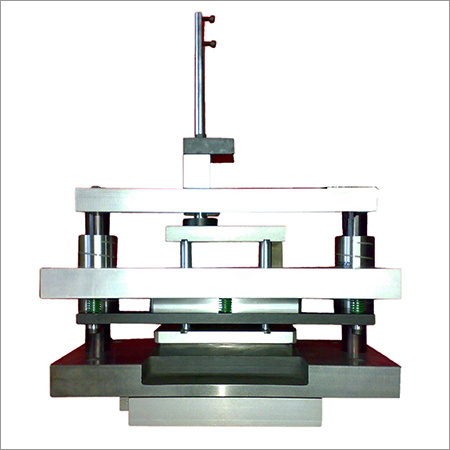

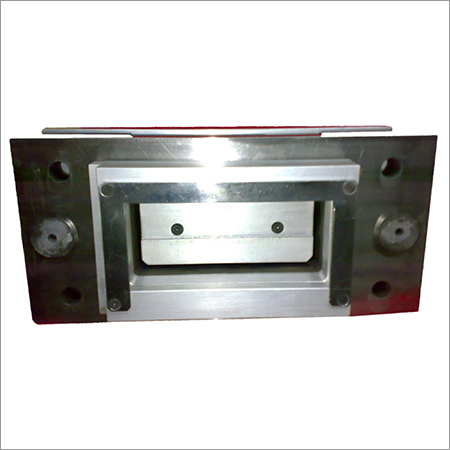

Precision-Crafted Cutting Dies for Industrial Excellence

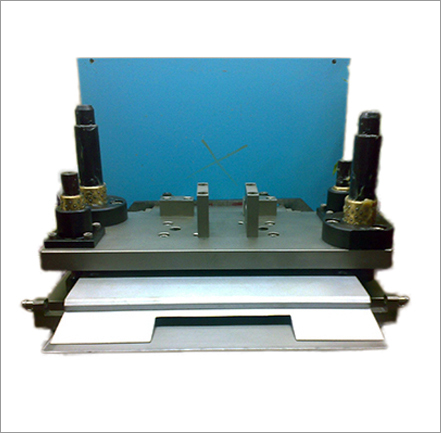

Our custom-designed cutting dies are meticulously crafted from high-grade steel and incorporate a precision ground mould base. They are vacuum hardened, ensuring long-term durability through up to one million cycles. Perfect for intricate stamping, forming, and cutting tasks across metal, plastic, or paper, these dies are ideal for manufacturing, packaging, and other industrial processes. Multiple die head and punch configurations are available to meet unique project needs.

Versatile Configurations and Enhanced Longevity

With multiple punch die configurations and customizable die heads, these tools adapt effortlessly to various shaping modes, including press mould operations. The high-speed steel core and replaceable, hardened die heads ensure consistent performance and minimize downtime. Engineered to maintain accuracy within a 0.01 mm tolerance, these dies guarantee highly reliable, repeatable results, maximizing productivity in high-demand environments.

FAQ's of Cutting Dies:

Q: How are the cutting dies manufactured to ensure durability and performance?

A: The cutting dies are fabricated using vacuum hardening, resulting in a cutting edge hardness between 58-62 HRC. The surface is polished for smooth operation, while a precision ground steel mould base and a high-speed steel (HSS) core provide strength and durability, supporting up to 1 million cuts.Q: What materials can these dies cut, and what thickness range do they support?

A: Our cutting dies are engineered for use with metal, plastic, and paper substrates, efficiently handling material thicknesses from 0.5mm up to 10mm. This versatility makes them ideal for various industrial cutting, forming, and stamping operations.Q: When should I choose a custom-sized die over a standard size?

A: A custom-sized die is recommended when your application demands unique shapes, specific material thicknesses, or non-standard dimensions that standard dies cannot address. Our team collaborates with you to design dies tailored precisely to your specifications.Q: Where are these cutting dies primarily used in industry?

A: These dies are extensively employed in industries such as manufacturing, packaging, metalworking, and paper processing. They are suitable for any process requiring consistent, high-precision cutting, shaping, or stamping.Q: What is the process for replacing the die head or punch dies?

A: Our dies are designed with replaceable, hardened die heads and multiple punch die configurations. This modular approach enables straightforward removal and replacement of worn components, reducing downtime and ensuring continued operational efficiency.Q: How does the 0.01 mm tolerance benefit my manufacturing process?

A: The tight tolerance of 0.01 mm ensures each cut is precise and consistent. This high accuracy reduces waste, enhances product quality, and helps meet stringent industry standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Dies Category

Press Tool Dies

Minimum Order Quantity : 01 Ton

Shaping Mode : Other

Mould Base : High Performance Metal Base

Life Span : Long Operational Life

Product Type : Pressure Tool Dies

Material : Other

Punching Tool

Minimum Order Quantity : 1 Piece

Shaping Mode : Other, Punching

Mould Base : Steel

Life Span : Up to 500,000 cycles

Product Type : Punching Tool

Material : Other

Industrial Dies

Minimum Order Quantity : 1 , , Unit

Shaping Mode : Die Casting

Mould Base : Standard Steel Base

Life Span : Up to 500,000 shots

Product Type : Industrial Dies

Material : Steel

Precision Dies

Minimum Order Quantity : 1 , , Unit

Shaping Mode : Other, Stamping/Injection

Mould Base : Steel Mould Base

Life Span : 10,00,000 shots

Product Type : Precision Dies

Material : Steel

Send Inquiry

Send Inquiry