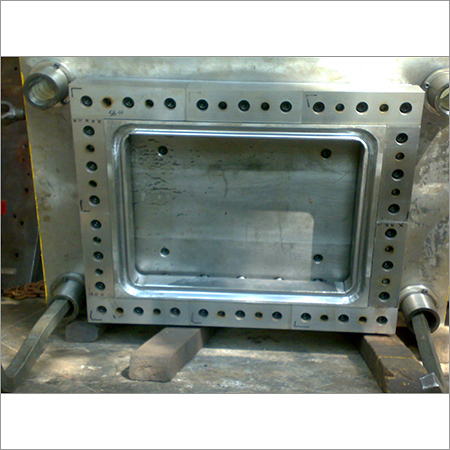

Vacuum Mould

Vacuum Mould Specification

- Machining Type

- Other

- Product Type

- Vacuum Mould

- Material

- Aluminum, Stainless Steel

- Application

- Molding and forming plastic components in vacuum forming processes

- Micro Machining

- Yes

- Surface Treatment

- Polished

- Tolerance

- 0.05 mm

- Capacity

- Custom as per design

- Color

- Silver (natural metal finish)

- Design Software

- AutoCAD, SolidWorks

- Lead Time

- 15-30 days

- Mould Life

- Up to 300,000 shots

- Size

- Customized as per application

- Usage

- Used for producing precise plastic and polymer parts by vacuum forming

- Runner System

- Cold or Hot runner (as per requirement)

- Hardness

- HRC 30-50 (varies by material)

- Packaging

- Standard export wooden box

- Manufacturing Process

- CNC machining, Electrical Discharge Machining (EDM)

- Mould Base

- Standard or customized

- Cavity Quantity

- Single or Multi-cavity options available

Vacuum Mould Trade Information

- Minimum Order Quantity

- 1 , , Number

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Vacuum Mould

R. K. Engineers is continuously meeting several requirements of clients by offering Vacuum Mould and other sheet metal pressed components. The designing and manufacturing processes are carried out by skilled and knowledgeable personnel, who use quality approved material and employs cutting-edge technology. This product is specially designed for industries where fabricated sheet metal, fiberglass is highly demanded. We are meeting the diverse client demands by providing Vacuum Mould in both, standard and customized technical specifications.

Features:

- Vacuum Mould is created to be dimensional accurate

- The operational fluency of mould is high

- The surface of the mould is thoroughly finished to assure durability

- Customers can rely on its operational efficiency

Precision Design and Manufacturing

Utilizing advanced CNC machining and EDM technologies, our vacuum moulds are designed in AutoCAD and SolidWorks to exact specifications. Each mould is carefully crafted for outstanding accuracy, ensuring a polished finish and precise tolerances, making them perfect for intricate plastic component fabrication.

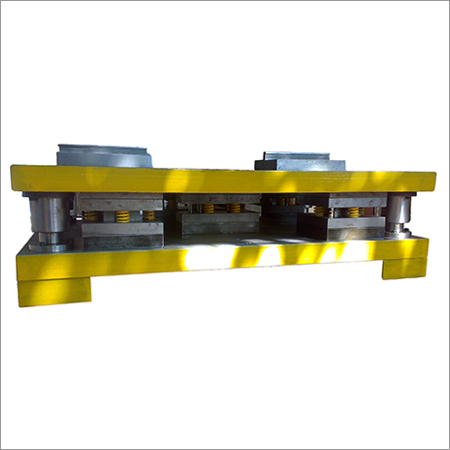

Durable Materials and Enhanced Mould Life

Constructed from premium aluminum or stainless steel, these vacuum moulds achieve a hardness range of HRC 30-50, resulting in enhanced wear resistance and durability. With an estimated life of up to 300,000 shots, manufacturers benefit from a reliable mould solution that minimizes downtime and maximizes productivity.

Versatile Applications and Customized Solutions

Offering customized sizes, cavity options, and runner systems to suit different production needs, our vacuum moulds support a wide range of applications in the plastic molding industry. Whether for precise prototyping or high-volume manufacturing, the moulds can be tailored to meet specific requirements.

FAQs of Vacuum Mould:

Q: How is the vacuum mould manufactured?

A: The vacuum mould is produced through advanced CNC machining and electrical discharge machining (EDM), ensuring high precision and exact tolerances.Q: What are the available cavity quantity options for these moulds?

A: Customers can choose between single or multi-cavity configurations, based on their production volume and application needs.Q: When can I expect the delivery of my vacuum mould?

A: Lead times typically range from 15 to 30 days, depending on the complexity of the design and customization requirements.Q: Where are these vacuum moulds used?

A: They are primarily utilized in industries for vacuum forming processes, molding precise plastic and polymer components.Q: What benefits does using a vacuum mould provide?

A: Vacuum moulds enable the production of highly accurate, consistent, and durable plastic parts, reducing material waste and enhancing manufacturing efficiency.Q: What is the process for customizing mould base and size?

A: Customers can specify their requirements for mould base and size, and the design is accommodated using AutoCAD or SolidWorks for tailored solutions.Q: How should the vacuum mould be packaged for shipping?

A: Each mould is securely packed in a standard export wooden box, ensuring protection during transit and safe delivery to the destination.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sheet Metal Pressed Components Category

Sheet Metal Parts

Minimum Order Quantity : 1 Set

Bending Angle : Up to 120

Hardness : Up to 60 HRC

Surface Finish : Smooth, Matte, Glossy, Polished

Dimension (L*W*H) : Customized Sizes

Material : Carbon Steel, Other

Sheet Metal Pressed Components

Minimum Order Quantity : 1 , , Unit

Bending Angle : Customizable as per design

Hardness : 4055 HRC

Surface Finish : Polished

Dimension (L*W*H) : As per customer requirement

Material : Carbon Steel, Other

Sheet Metal Dies

Minimum Order Quantity : 1 Unit

Bending Angle : Up to 120

Hardness : 5862 HRC

Surface Finish : Mirror / Matte

Dimension (L*W*H) : Customized (As per drawing)

Material : Other

Send Inquiry

Send Inquiry