Sheet Metal Pressed Components

Sheet Metal Pressed Components Specification

- Surface Finish

- Polished

- Dimension (L*W*H)

- As per customer requirement

- Thickness

- 0.5 mm to 8 mm

- Hardness

- 40-55 HRC

- Bending Angle

- Customizable as per design

- Machining Type

- Other

- Product Type

- Other

- Material

- Carbon Steel

- Application

- Industrial Machine, Automation Machine

- Micro Machining

- No

- Surface Treatment

- Zinc Plated

- Tolerance

- 0.05 mm

- Capacity

- Up to 100 Ton

- Standards

- ISO 2768

- Process

- Stamping, Bending, Punching

- Usage

- Automotive, Electrical, Industrial Machinery

- Color

- Silver

- Corrosion Resistance

- Yes

- Shape

- Rectangular, Customized

- Packaging Type

- Box, Carton

- Feature

- High Strength, Durable

- Weight

- Custom/As per design

Sheet Metal Pressed Components Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Delivery Time

- 10 Days

- Main Export Market(s)

- South America, Central America, Asia, Eastern Europe, Middle East, Western Europe, North America, Australia, Africa

- Main Domestic Market

- All India

About Sheet Metal Pressed Components

R. K. Engineers is a reliable manufacturing and exporting company that can make available Sheet Metal Pressed Components to automobile, textile, and many other industries. These components can include automobile components, textile machine components, welded assemblies, and sheet metal parts for several industries, based on the customer requirements. These manufacturing industries use the components for several purposes. We use special metal alloys in the fabrication process, based on the cutting-edge technology.

Features of Sheet Metal Pressed Components:

- We offer these components in compact design

- These components have impeccable finish

- These are resistant to corrosion

- These have long functional life

Precision Engineered Components

Each sheet metal pressed component is produced using cutting-edge machinery and rigorous quality checks. Adhering to ISO 2768 standards, we guarantee high-precision and consistently reliable parts for critical applications. Our processes ensure optimal dimensional accuracy and performance, making our products the preferred choice for demanding industries.

Versatility and Customization

We offer fully customizable solutions-including rectangular shapes, variable thickness, weights, and bending angles-to meet unique project needs. Our components serve a variety of sectors such as automotive, electrical, and industrial machinery. By collaborating closely with customers, we deliver tailored components for both standard and intricate automation requirements.

Durability and Surface Protection

Constructed from robust carbon steel and finished with zinc plating and a polished surface, our components promise enhanced longevity and exceptional corrosion resistance. These features, combined with 40-55 HRC hardness and tolerances of 0.05 mm, ensure reliable performance in harsh industrial environments, guaranteeing excellent value and reduced maintenance costs.

FAQ's of Sheet Metal Pressed Components:

Q: How are your sheet metal pressed components manufactured?

A: Our components are manufactured using advanced stamping, bending, and punching processes. We utilize high-strength carbon steel and adhere to ISO 2768 standards, ensuring dimensional accuracy and precision. The production process includes stringent quality control, surface treatments (zinc plating, polishing), and careful packaging to maintain component integrity.Q: What customization options are available for these components?

A: We offer a wide range of customization options, including shape (rectangular), dimensions (L*W*H), thickness (0.5 mm to 8 mm), bending angles, hardness (40-55 HRC), and weight preferences. Customers can specify their requirements, and we tailor the manufacturing process to deliver components that precisely meet their project needs.Q: When should I choose your sheet metal pressed components for my application?

A: Our components are ideal for applications that demand high strength, durability, and corrosion resistance. They are particularly suited for automotive, electrical, and industrial machinery or automation machines where reliability and precision are critical. Choose our products if you require parts manufactured to exact specifications with robust performance across various operating environments.Q: Where can your sheet metal pressed components be used?

A: These components are utilized across a variety of industries, including automotive, electrical, industrial machinery, and automation technology. Their customizability and resilience make them suitable for both standard installations and specialized machinery in large-scale industrial setups.Q: What surface treatments and finishes do you provide?

A: We provide zinc plating and polishing as standard surface treatments, which enhance corrosion resistance and give each component a refined silver finish. These treatments not only extend the service life of the products but also maintain their appearance and functionality in demanding environments.Q: How does your packaging ensure the safety of the components during transit?

A: We use durable packaging options such as boxes and cartons, specifically chosen to protect the components from mechanical damage, moisture, and corrosion during transportation. This approach guarantees that all products arrive at their destination in pristine condition, ready for immediate installation or further processing.Q: What are the key benefits of using your pressed components over standard alternatives?

A: Our pressed components offer superior strength, precise tolerances (0.05 mm), and exceptional customization not typically available in off-the-shelf products. With enhanced corrosion resistance, customizable hardness, and professional surface finishing, our solutions deliver long-term reliability and reduced maintenance for mission-critical industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sheet Metal Pressed Components Category

Sheet Metal Parts

Minimum Order Quantity : 1 Set

Product Type : Other, Sheet Metal Parts

Tolerance : 0.05 mm

Surface Treatment : Other, Galvanized, Powder Coating, Painting, Anodizing

Material : Carbon Steel, Other

Application : Other, Automotive, Electronics, Electrical Cabinets, Construction, Machinery Parts, Industrial Equipment

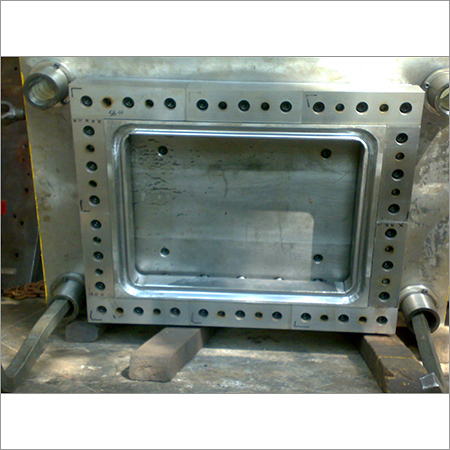

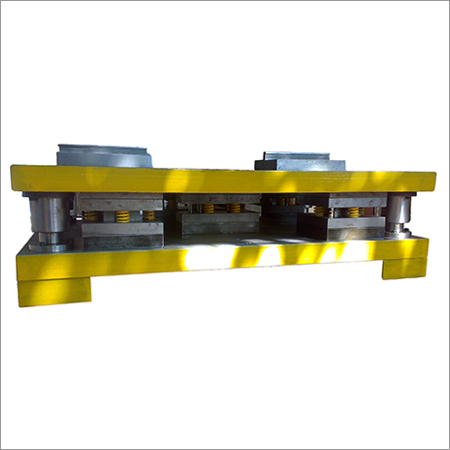

Sheet Metal Dies

Minimum Order Quantity : 1 Unit

Product Type : Other

Tolerance : 0.01 mm

Surface Treatment : Other, Polished

Material : Other

Application : Industrial Machine, Automobile

Vacuum Mould

Minimum Order Quantity : 1 , , Number

Product Type : Other, Vacuum Mould

Tolerance : 0.05 mm

Surface Treatment : Other, Polished

Material : Other, Aluminum, Stainless Steel

Application : Other, Molding and forming plastic components in vacuum forming processes

Send Inquiry

Send Inquiry