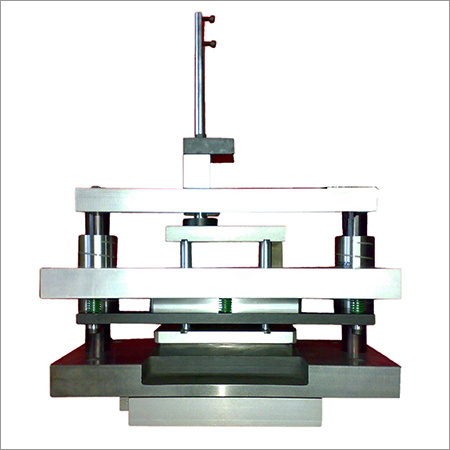

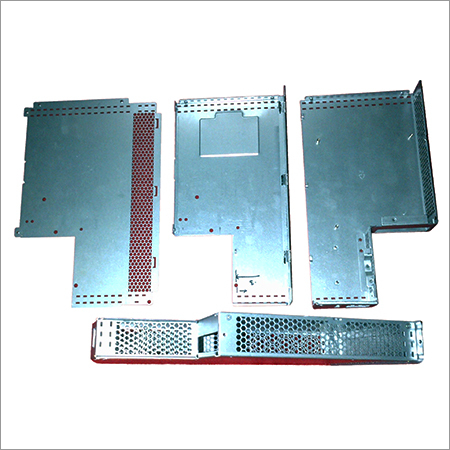

Industrial Dies

Industrial Dies Specification

- Working Process

- Precision Machining, CNC, EDM

- Core Material

- Hardened Steel

- Tolerance

- 0.01 mm

- Life Span

- Up to 500,000 shots

- Mould Base

- Standard Steel Base

- Usage

- Die Casting

- Material

- Steel

- Shaping Mode

- Die Casting

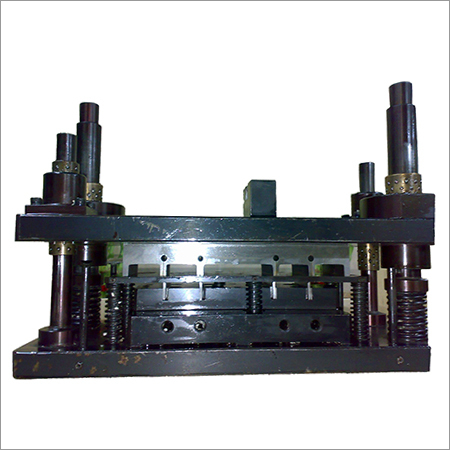

- Punch Dies

- High Precision Punches

- Product Type

- Industrial Dies

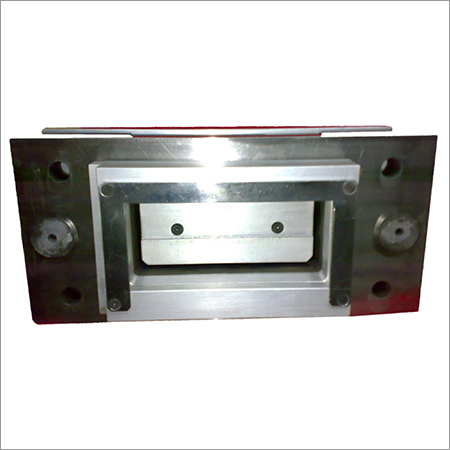

- Die Head

- Interchangeable Die Assembly

- Color

- Silver

Industrial Dies Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Delivery Time

- 10 Days

- Main Export Market(s)

- Central America, Asia, Australia, North America, Middle East, South America, Western Europe, Africa

- Main Domestic Market

- All India

About Industrial Dies

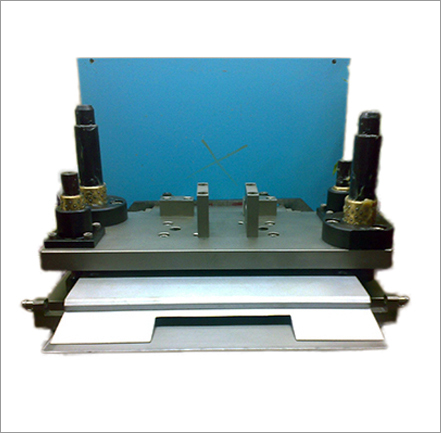

With over 15 years of experience in the engineering field, we efficiently cater to the requirements of clients, which are majorly industrial sectors. The Industrial Dies in the offering are developed by skilled professionals in several sizes and patterns. Manufacturing industries use these industrial dies for cutting and shaping material. The different operations these dies can perform are bending, stretching and blanking.

Features of Industrial Dies:

- The dies are superbly finished

- These are constructed robustly

- These are resistant to corrosion

- These are dimensionally accurate

Precision Manufacturing for Superior Performance

Our dies are produced using advanced CNC and EDM techniques to ensure exacting standards and superior performance. The use of hardened steel and standard steel bases enhances strength and longevity, supporting rigorous industrial processes. The precision machining provides minimal tolerance deviations, enabling reliable and repeatable results for every batch.

Applications Across Multiple Industries

Designed for use in automotive, electrical, and packaging sectors, these dies meet diverse manufacturing needs. Their customizable features and robust construction make them suitable for both mass production and specialized casting tasks. Available customization ensures optimal fit for various industrial projects and innovations.

FAQ's of Industrial Dies:

Q: How are these industrial dies customized to meet client specifications?

A: We offer customization of dies based on the clients' drawings and requirements. You can specify dimensions, cavity number (single or multiple), and application industry needs to ensure the die is tailored for optimal performance in your processes.Q: What is the process involved in manufacturing these dies?

A: The dies are manufactured using advanced precision machining, including CNC and EDM techniques. The process also involves surface polishing, case hardening, and assembling with high precision punches and interchangeable die heads to guarantee accuracy and durability.Q: When should these dies be used in manufacturing?

A: These dies are ideal for applications where high precision, consistent output, and long tool life are critical, such as in the automotive, electrical, and packaging industries. They are best utilized when production demands require up to 500,000 shots or more.Q: Where can these dies be applied within the industry?

A: Our dies are extensively used in die casting processes to manufacture components for automotive parts, electrical housings, and packaging solutions. Their versatility also allows application in custom projects tailored to client specifications.Q: What benefits do the case hardened and polished finishes provide?

A: A case hardened surface greatly increases wear resistance and lifespan, while polished finishes reduce friction, ensuring smoother operations and improving the surface quality of the cast parts.Q: How does the die's tolerance and lifespan impact production quality?

A: With a tolerance of 0.01 mm and a lifespan of up to 500,000 shots, our dies ensure high accuracy, minimal dimensional variance, and extended operational efficiency, minimizing downtime and production waste.Q: What are the main advantages of using interchangeable die assembly and high precision punch dies?

A: Interchangeable die assemblies and high precision punch dies enhance flexibility, reduce maintenance time, and provide adaptability for producing different components without changing the entire die setup.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Dies Category

Press Tool Dies

Minimum Order Quantity : 01 Ton

Punch Dies : Tempered Steel Punches

Color : Silver

Material : Other

Working Process : Other

Cutting Dies

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Punch Dies : Multiple configurations available

Color : Black

Material : Steel

Working Process : Other, Stamping, Forming, Cutting

Punching Tool

Price 10000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Punch Dies : Replaceable, carbidetipped

Color : Grey

Material : Other

Working Process : Other, Precision Punching

Precision Dies

Minimum Order Quantity : 1 , , Unit

Punch Dies : Carbide/Steel Punch Dies

Color : Silver

Material : Steel

Working Process : Other, Precision Machining, EDM, CNC Milling

Send Inquiry

Send Inquiry