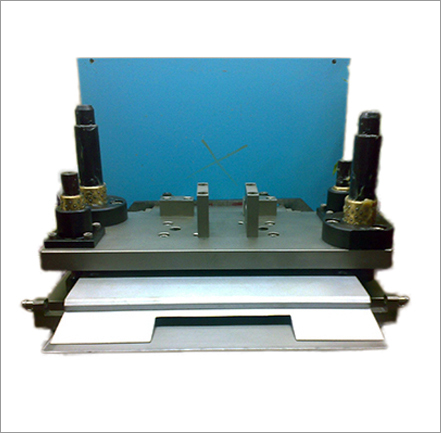

Precision Dies

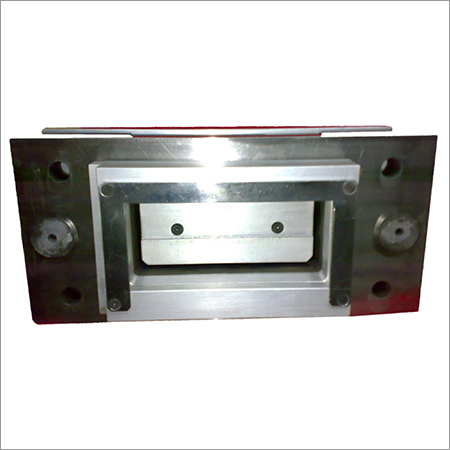

Precision Dies Specification

- Tolerance

- 0.005 mm

- Mould Base

- Steel Mould Base

- Core Material

- High-grade Alloy Steel

- Life Span

- 10,00,000 shots

- Working Process

- Precision Machining, EDM, CNC Milling

- Usage

- Industrial

- Material

- Steel

- Shaping Mode

- Stamping/Injection

- Punch Dies

- Carbide/Steel Punch Dies

- Product Type

- Precision Dies

- Die Head

- Hardened Steel Die Head

- Color

- Silver

Precision Dies Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Cash Advance (CA), Telegraphic Transfer (T/T), Cheque

- Delivery Time

- 10 Days

- Main Export Market(s)

- Central America, Asia, North America, Eastern Europe, Middle East, South America, Western Europe, Australia, Africa

- Main Domestic Market

- All India

About Precision Dies

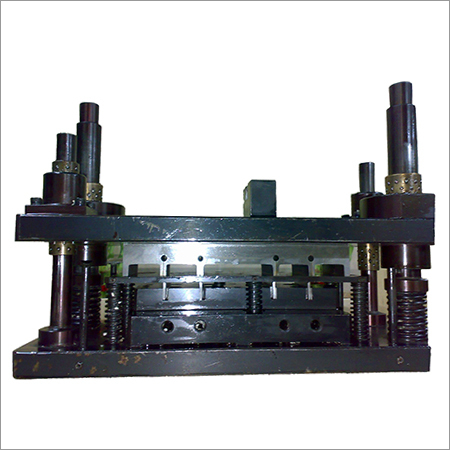

Of many industrial dies that R. K. Engineers manufactures and exports, Precision Dies are widely demanded dies suitable several industrial sector applications. The specialized tool can be used for shaping material into desired shapes. Customers can avail from us Precision Dies that are efficient, high performance and durable dies.

Feature:

- These are precision dies because of their precise engineering

- These are high strength dies with high tolerance capacity

- Users can use these durable dies for long

High-Quality Surface Finish

Every Precision Die features a meticulously polished and ground finish, ensuring uniformity and minimal friction during operation. This results in excellent mold release and extended tool life, especially critical in industries where accuracy and consistency are paramount.

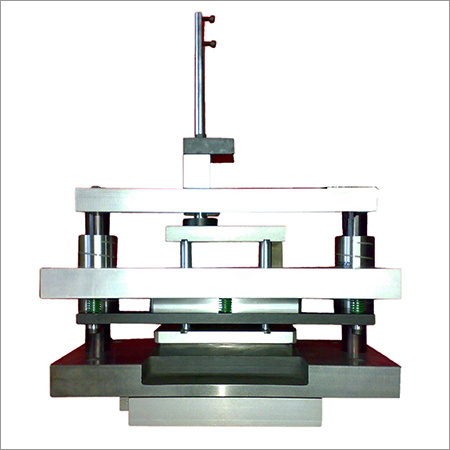

Tailored for Diverse Applications

Whether you are servicing the automotive or electronics sector, these dies can be customized for a variety of complex shapes and dimensions. The robust mould base and precision punch dies support both stamping and injection processes, maximizing flexibility in manufacturing.

Superior Materials & Longevity

Crafted from hardened steel and high-grade alloy steel, our dies exhibit a remarkable hardness of 58-62 HRC. Combined with careful heat treatment and advanced machining techniques, they deliver a lifespan of up to 1,000,000 shots, ensuring reliability for mass production.

FAQ's of Precision Dies:

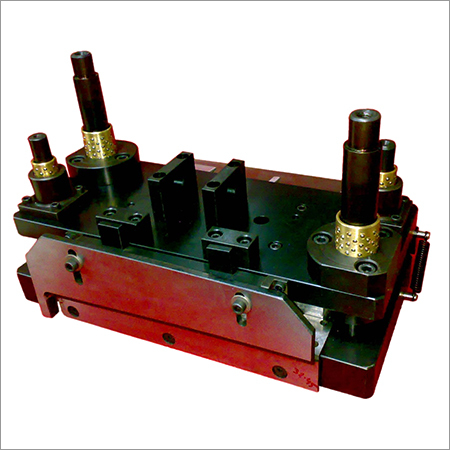

Q: How are Precision Dies manufactured to achieve high accuracy and surface quality?

A: Precision Dies are made using advanced machining processes including precision CNC milling and Electrical Discharge Machining (EDM). Each die undergoes thorough polishing and grinding, followed by case hardening, to achieve outstanding dimensional accuracy and a surface finish ideal for high-precision industrial applications.Q: What customization options are available for these Precision Dies?

A: We offer extensive customization, including dimensions, die shapes, tolerance levels, and material selection according to client specifications. Whether you need dies for a unique automotive part or a specific electronic component, our team will develop solutions tailored to your production needs.Q: When should I choose a case-hardened die with carbide or steel punch options?

A: Case-hardened dies with carbide or high-grade steel punches are ideal for demanding applications requiring durability and resistance to wear. If your manufacturing process involves high-volume stamping or injection molding with tight tolerances, these features ensure minimal tool degradation and consistent part quality.Q: Where are these Precision Dies typically used?

A: They are widely employed in automotive and electronics manufacturing industries for producing components that require stringent tolerances and surface finishes. The robustness and accuracy of these dies make them suitable for any industrial setting where reliable, repeatable production is essential.Q: What is the benefit of choosing a die with 0.005 mm tolerance?

A: A tight tolerance of 0.005 mm ensures each produced part aligns closely with precise engineering requirements, minimizing variations and material wastage. This level of accuracy is especially beneficial in industries where product fit and performance are critical, like automotive and electronics.Q: How does secure box packing help during shipment?

A: Secure box packing protects the precision dies from physical damage, moisture, and contamination during transit and storage. This ensures the dies retain their accuracy and surface quality until they reach your facility for production use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Dies Category

Cutting Dies

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Shaping Mode : Other, Press Mould

Die Head : Hardened, Replaceable

Tolerance : 0.01 mm

Punch Dies : Multiple configurations available

Press Tool Dies

Minimum Order Quantity : 01 Ton

Shaping Mode : Other

Die Head : Precision Ground Die Head

Tolerance : 0.02 mm

Punch Dies : Tempered Steel Punches

Punching Tool

Price 10000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Shaping Mode : Other, Punching

Die Head : Hardened Steel

Tolerance : 0.01 mm

Punch Dies : Replaceable, carbidetipped

Precision Tool Dies

Minimum Order Quantity : 1 , , Unit

Shaping Mode : Die Casting

Die Head : Precision Hardened Steel

Tolerance : 0.01 mm

Punch Dies : Interchangeable Inserts

Send Inquiry

Send Inquiry